|

|

|

|

|

|

|

| WORN-OUT CRUSHER HAMMERS BEFORE REPAIREMENT & HARDFACING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| CRUSHER HAMMERS AFTER REPAIREMENT & HARDFACING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| WORN-OUT CRUSHER ROTOR BEFORE REPAIREMENT & HARDFACING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| CRUSHER ROTOR AFTER REPAIREMENT & HARDFACING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WORN-OUT GRINDING TABLE SEGMENTS FOR VERTICAL

MILL BEFORE REPAIREMENT & HARDFACING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| GRINDING TABLE SEGMENTS FOR VERTICAL MILL AFTER REPAIREMENT & HARDFACING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| RAW MILL PROTECTION RING FOR MAIN SHAFT BEFORE HARDFACING ONLY ON SIDE SUPPORTS-DIAGONAL STRUTS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| RAW MILL PROTECTION RING FOR MAIN SHAFT AFTER HARDFACING ON DIAGONAL STRUTS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| WORN-OUT ROLLER PRESS BEFORE REPAIREMENT & HARDFACING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ROLLER PRESS AFTER REPAIREMENT & HARDFACING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| WORN-OUT ROLLER-TIRE BEFORE REPAIREMENT & HARDFACING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ROLLER-TIRE AFTER REPAIREMENT & HARDFACING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SEPERATOR AIR CONE PARTS WITH HARDFACING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

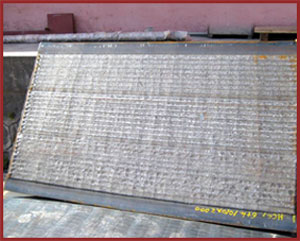

HARDFACED - COATED WEAR PLATES WITH THE

HARDNESS VALUE OF 65 HRC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

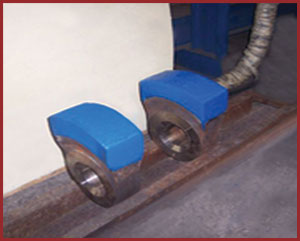

| HAMMERS READY FOR COATING - HARDFACING PROCESS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| HAMMERS AFTER COATING - HARDFACING PROCESS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| REPAIRED & HARDFACED CRUSHER ROTOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SEPERATOR WINGS WITH HARDFACING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| HOUSING BEFORE OVERLAYING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PRESS BODY BEFORE OVERLAYING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PRESS BODY AFTER OVERLAYING |

|

|

|

|

|

|

|